2014

N FACADE PANELS

SAN FRANCISCO, CA

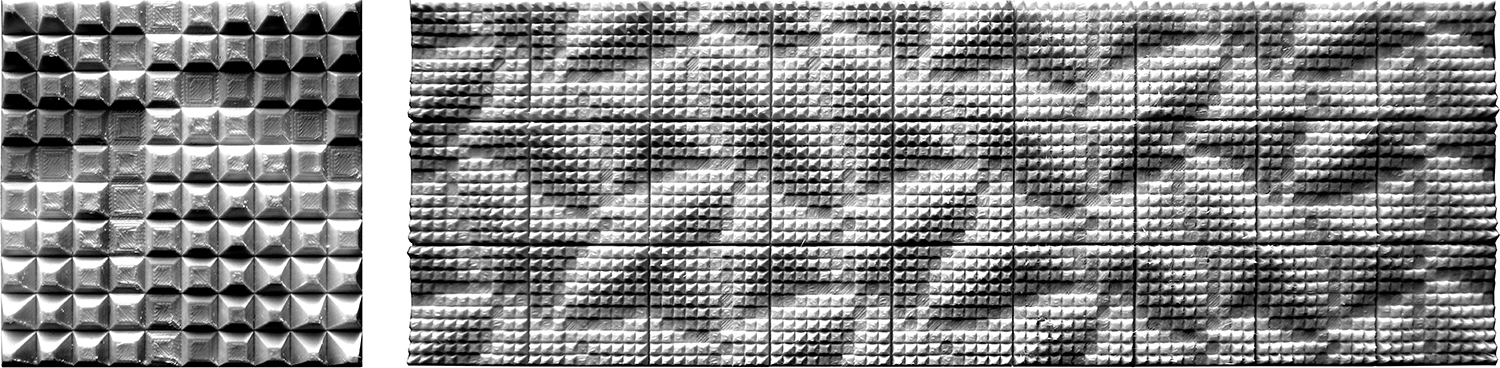

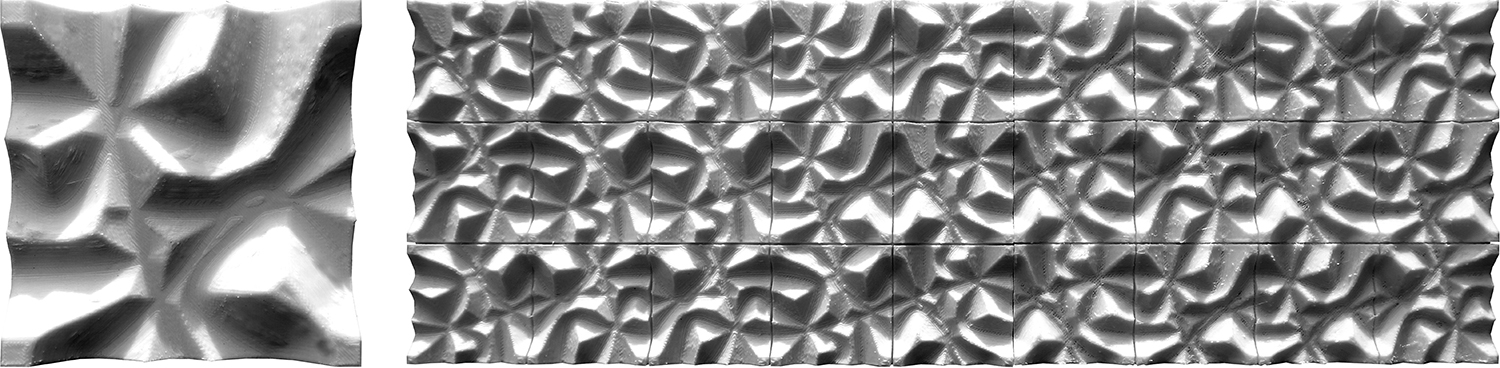

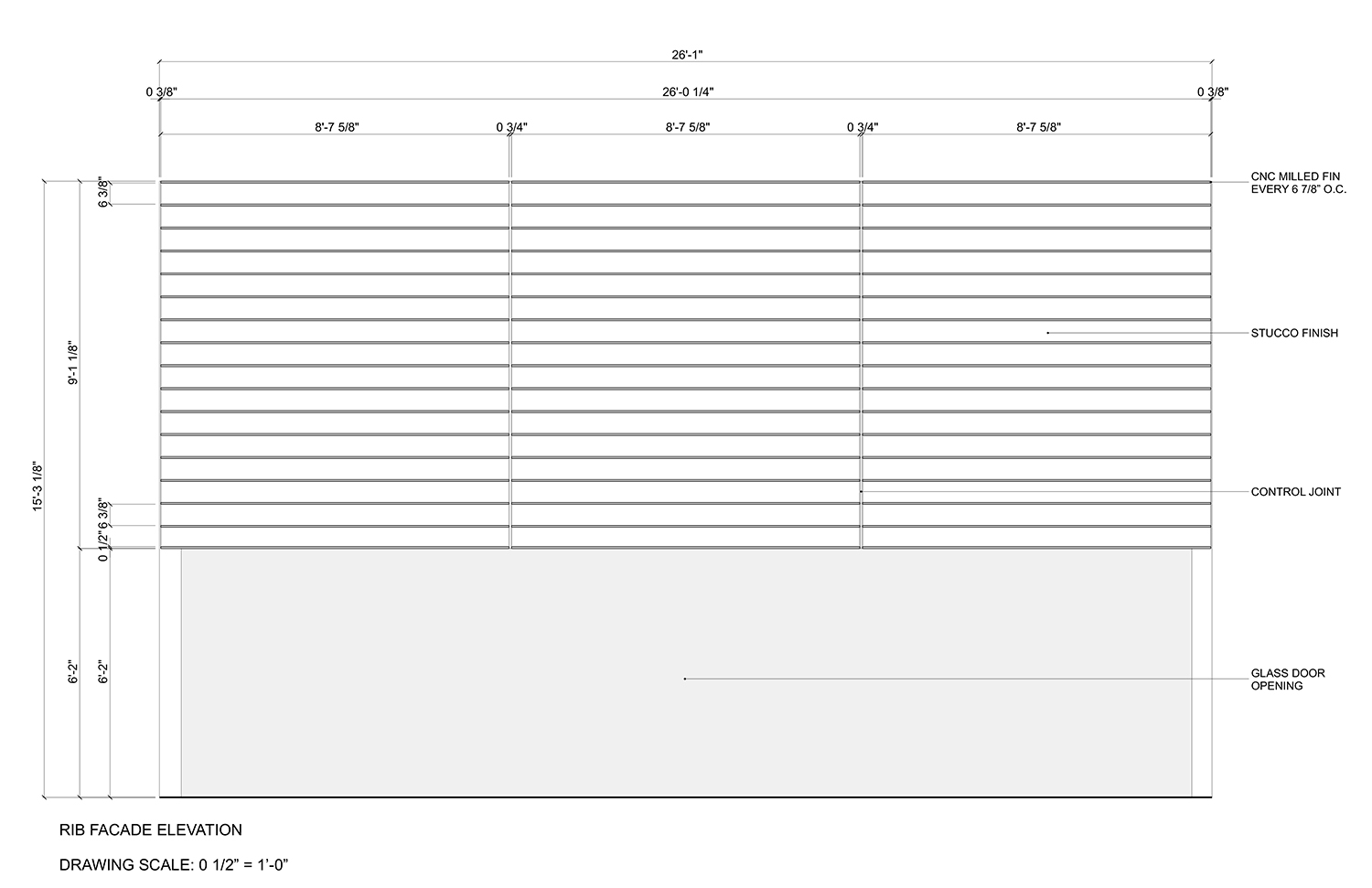

| Strategy 1: The 4n Panel We sought to create a panelized façade system that could imply dynamic movement while benefiting from repetition and economies of scale. These panels use a series of control points to match edge conditions, allowing the eccentric topography to continue from one panel to the next, regardless of the panel orientation. As such, each panel has four possible positions, allowing for a vast number of different surface patterns, all generated from a single cast-concrete mold. We applied this system to a variety of different surface geometries, deploying the same logic to create a wide array of aesthetic conditions. Strategy 2: The Depth of the Joint The surface continuity of stucco facades are generally disrupted by the necessity of expansion joints to allow for the movement of material in various conditions over time. The result is typically the visual “panelization” of a material that is applied continuously, in situ. In this study, we seek to capitalize on the expansion joint as a way to generate a new surface continuity (rather than discontinuity) for the stucco façade. In Version A, water jet cut steel fins form long, horizontal waves and act as expansion joints. Stucco is filled in between the fins, serving as relief for the “true” surface implied by the undulating contours of the break lines. In Version B, the same expansion fins serve as a guide for the contoured forms. A custom trowel with notches uses the fins as a guide to run over the stucco, allowing for the simple construction of a sculptural stucco façade. |